CoyoteSat

Launching NYC into low-Earth orbit through small satellite development

Role

Lead Structural Engineer

Industry

Aerospace

Duration

2.5 years

Project Mission

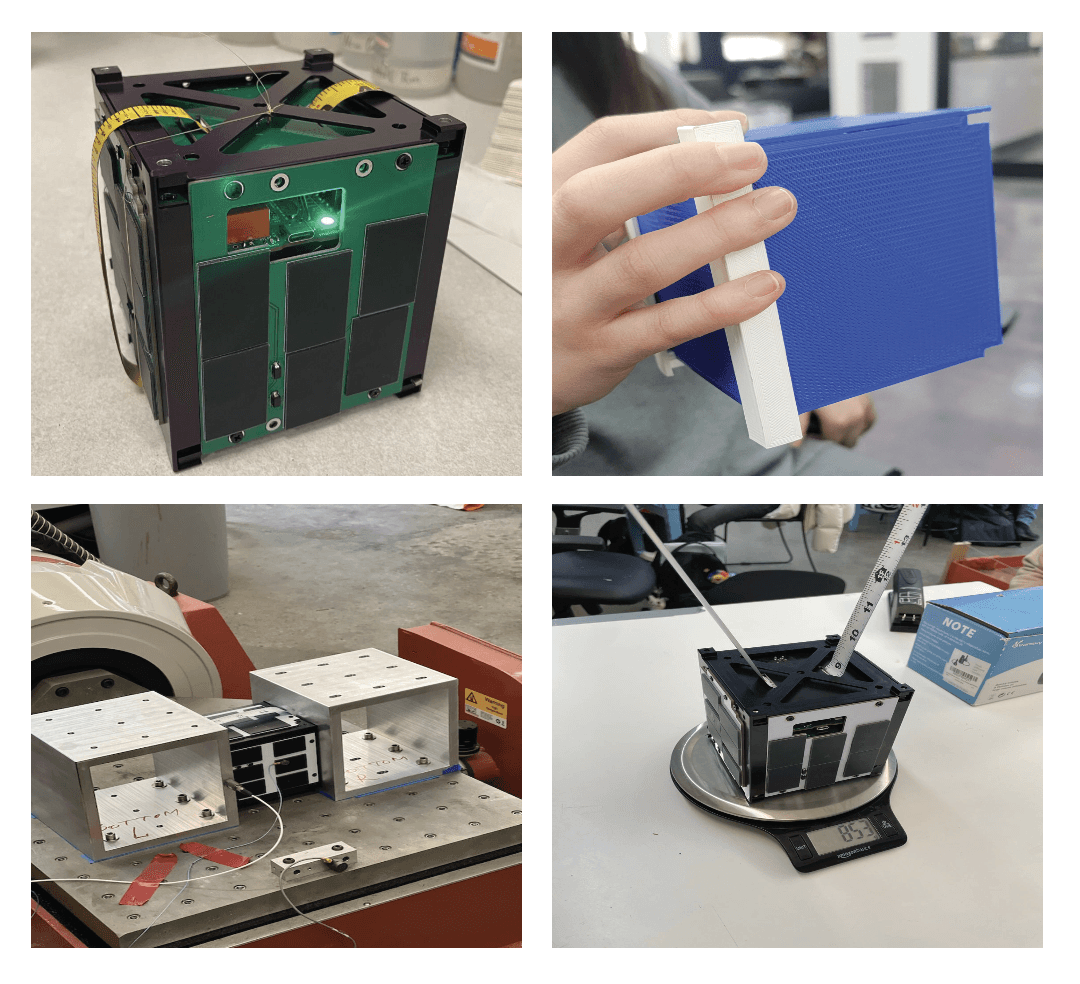

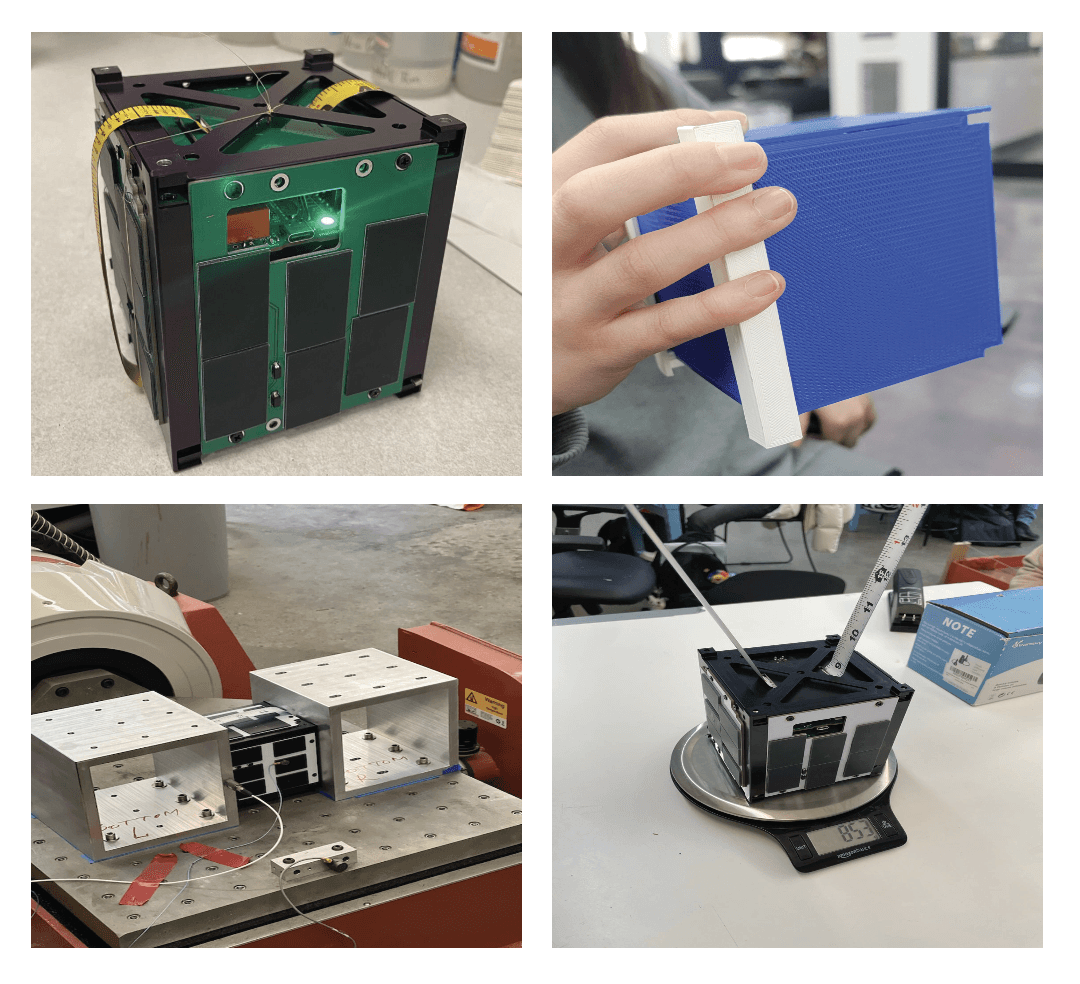

Creating hands-on aerospace experience for college students in NYC by designing and manufacturing a cube satellite (CubeSat) that detects gamma rays in low-Earth orbit using a modified version of the Cosmic Watch Muon Detector. This will allow us to further understand the effects of cosmic radiation on small spacecraft, and how we can develop lighter and resistant materials for in-space usage. The CoyoteSat will be launched into orbit in the near future!

Design Process

Our primary challenge was balancing structural integrity with budget constraints and strict guidelines. CubeSat development can cost $3,500-$50,000. To optimize resources, we used affordable, durable materials such as aluminum 6061 and machined as many parts as we could using CNC machines and water jets in NYU’s MakerSpace. We iterated on numerous 3D-modeled designs, prototyped, performed finite element analysis, tested, and finally manufactured the CoyoteSat. The most important part of this process was researching what materials perform best for the space environment.

Project Mission

Creating hands-on aerospace experience for college students in NYC by designing and manufacturing a cube satellite (CubeSat) that detects gamma rays in low-Earth orbit using a modified version of the Cosmic Watch Muon Detector. This will allow us to further understand the effects of cosmic radiation on small spacecraft, and how we can develop lighter and resistant materials for in-space usage. The CoyoteSat will be launched into orbit in the near future!

Design Process

Our primary challenge was balancing structural integrity with budget constraints and strict guidelines. CubeSat development can cost $3,500-$50,000. To optimize resources, we used affordable, durable materials such as aluminum 6061 and machined as many parts as we could using CNC machines and water jets in NYU’s MakerSpace. We iterated on numerous 3D-modeled designs, prototyped, performed finite element analysis, tested, and finally manufactured the CoyoteSat. The most important part of this process was researching what materials perform best for the space environment.

Other projects

Connect with me,

Let’s talk projects, collaborations, or anything design!

Connect with me,

Let’s talk projects, collaborations, or anything design!

Connect with me,

Let’s talk projects, collaborations, or anything design!

Copyright 2026 by Eva Ahmetaj

Copyright 2026 by Eva Ahmetaj

Copyright 2026 by Eva Ahmetaj