Aquall-E

A remote-operated aquatic device for safer water-surface waste collection

Role

Engineer

Industry

EnvTech · Climate & Sustiainability

Duration

1 year

Goal:

Cleaning waste from water surfaces is often slow, labor-intensive, and unsafe. Aquall-E reduces the need for human exposure by remotely navigating waterways and collecting floating debris—making water cleanup safer and more accessible.

Design Process:

Aquall-E was developed under two primary constraints: a $1,500 total budget and a minimum physical size requirement driven by waste collection efficiency.

To avoid frequent returns to shore, the collection basket needed sufficient volume to store debris during operation. This requirement directly increased the vehicle’s size and weight, which in turn demanded higher-power thrusters. Thrusters ultimately accounted for nearly one-third of the total budget, forcing careful cost optimization across the rest of the system.

Design decisions were continuously evaluated against performance, cost, and manufacturability tradeoffs.

Aquall-E was designed and analyzed using CAD, CAM, and ANSYS, and fabricated through a combination of CNC milling, welding, and 3D printing.

Performance Requirements

The system was designed to meet the following measurable criteria:

Operational endurance: Minimum 1 hour of operation from full battery at launch

Loaded performance: Minimum speed of 3 ft/s while carrying up to 5 lbs of collected debris

Unloaded performance: Minimum speed of 6 ft/s with no payload

Durability: Withstands a 3 ft drop without functional failure

Goal:

Cleaning waste from water surfaces is often slow, labor-intensive, and unsafe. Aquall-E reduces the need for human exposure by remotely navigating waterways and collecting floating debris—making water cleanup safer and more accessible.

Design Process:

Aquall-E was developed under two primary constraints: a $1,500 total budget and a minimum physical size requirement driven by waste collection efficiency.

To avoid frequent returns to shore, the collection basket needed sufficient volume to store debris during operation. This requirement directly increased the vehicle’s size and weight, which in turn demanded higher-power thrusters. Thrusters ultimately accounted for nearly one-third of the total budget, forcing careful cost optimization across the rest of the system.

Design decisions were continuously evaluated against performance, cost, and manufacturability tradeoffs.

Aquall-E was designed and analyzed using CAD, CAM, and ANSYS, and fabricated through a combination of CNC milling, welding, and 3D printing.

Performance Requirements

The system was designed to meet the following measurable criteria:

Operational endurance: Minimum 1 hour of operation from full battery at launch

Loaded performance: Minimum speed of 3 ft/s while carrying up to 5 lbs of collected debris

Unloaded performance: Minimum speed of 6 ft/s with no payload

Durability: Withstands a 3 ft drop without functional failure

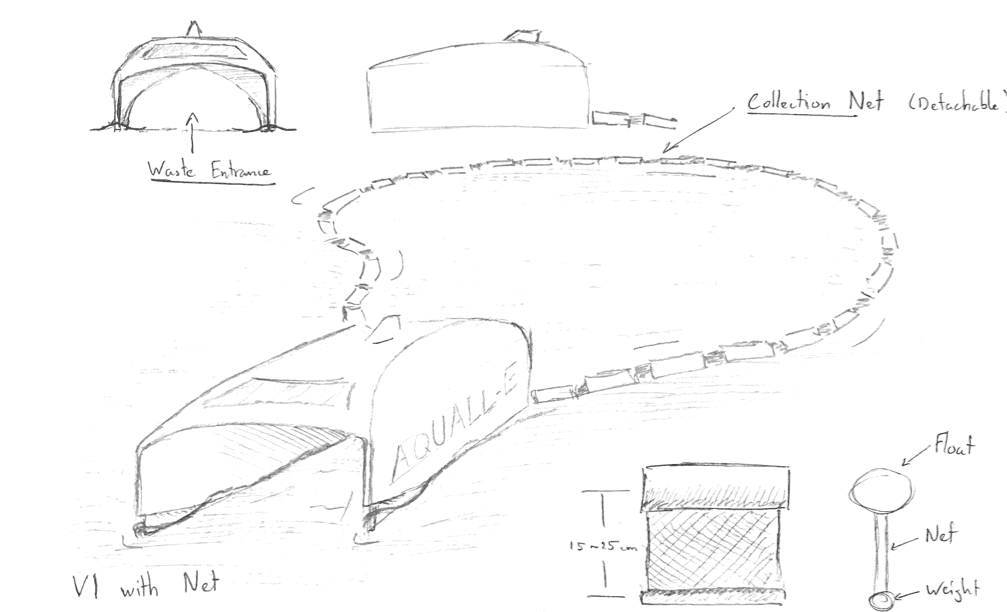

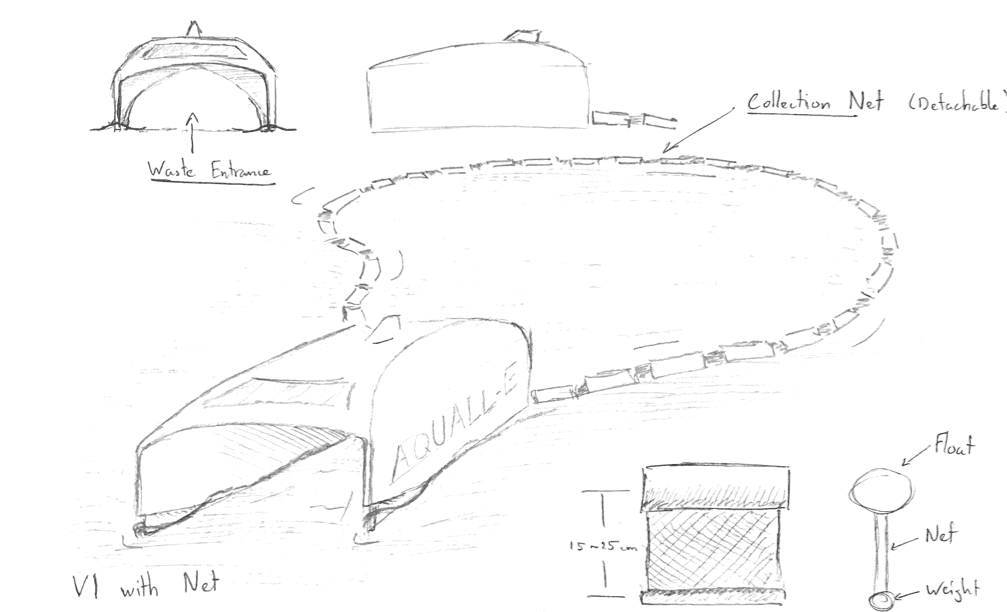

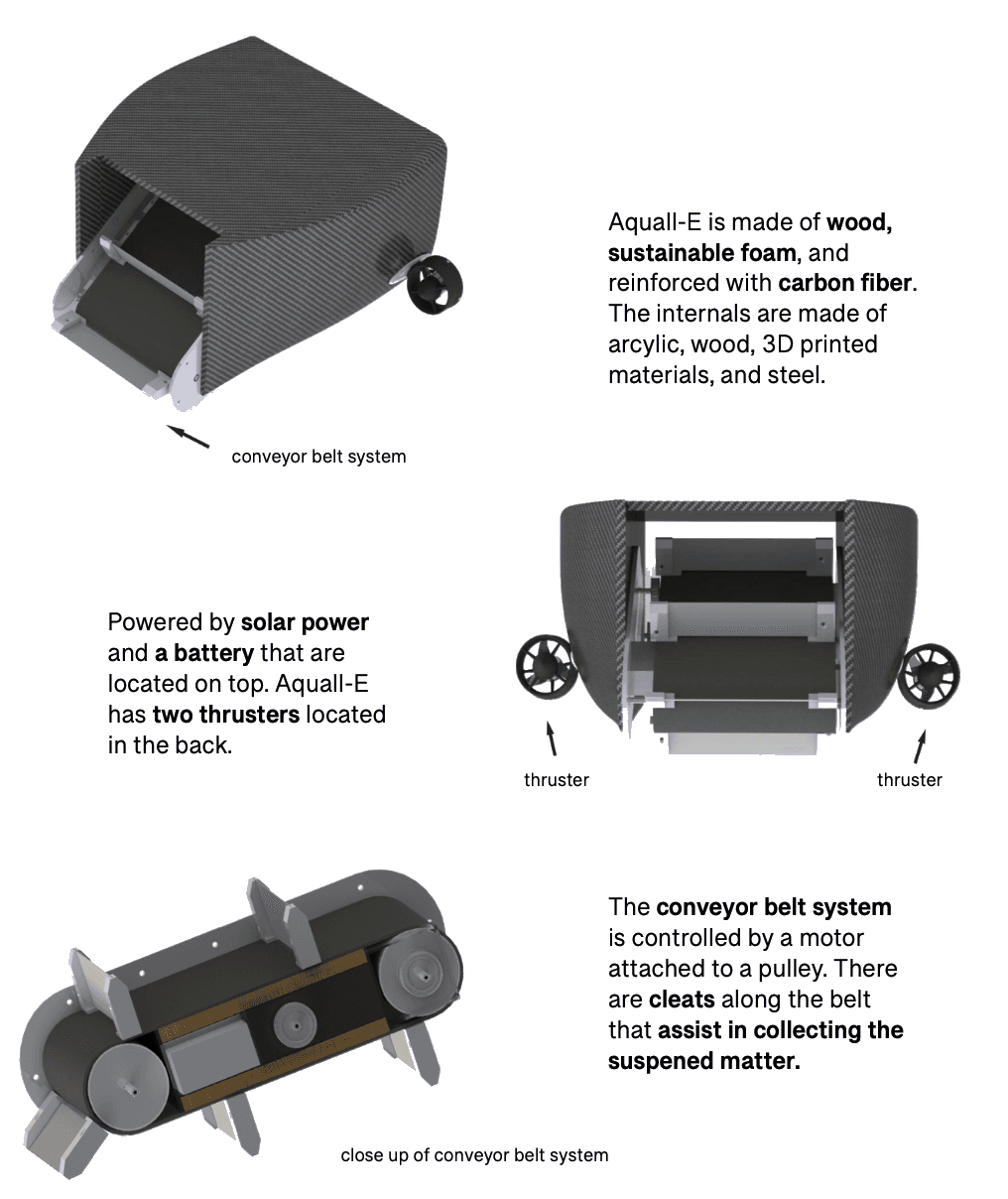

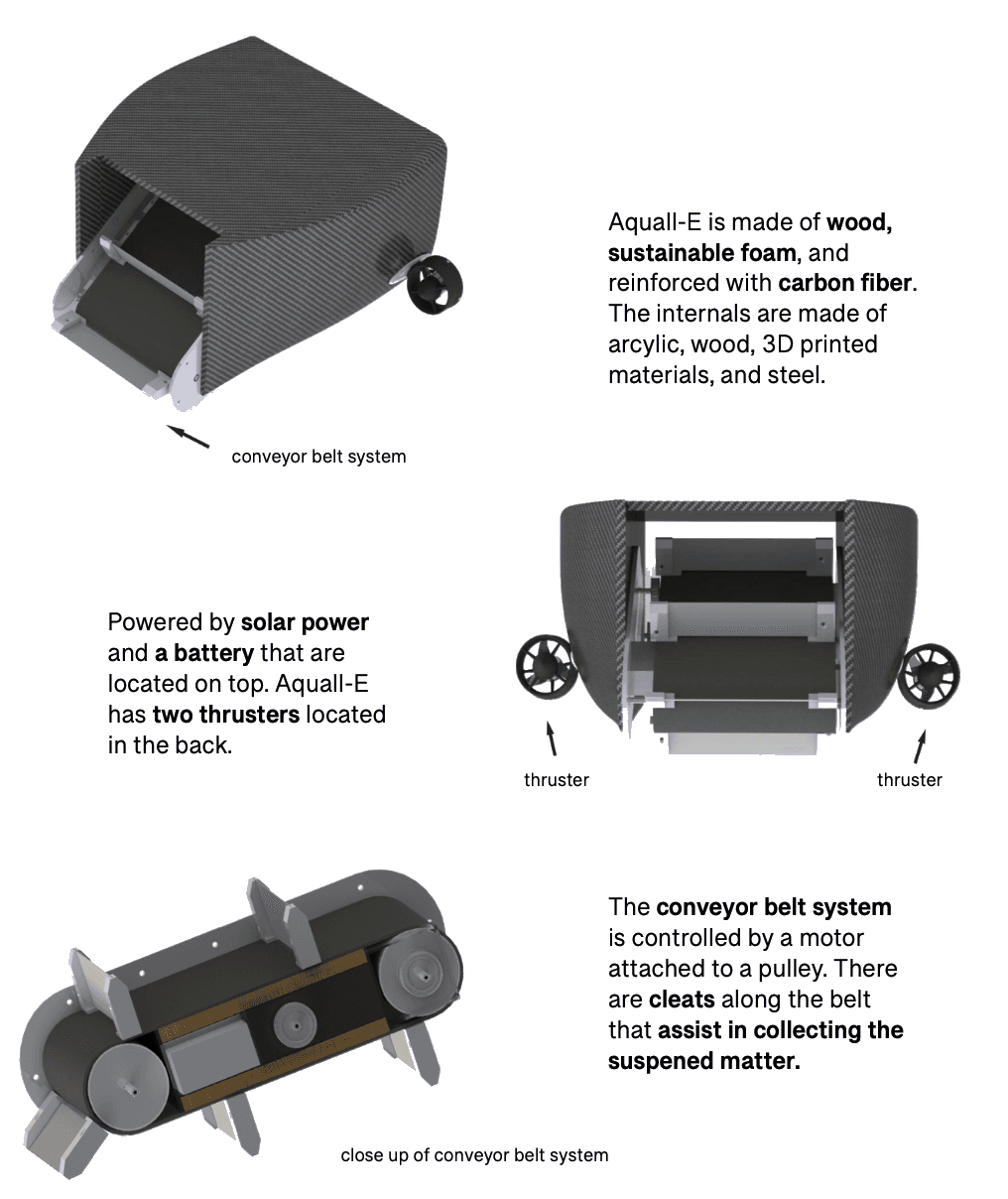

Final Design:

Final Design:

Other projects

Connect with me,

Let’s talk projects, collaborations, or anything design!

Connect with me,

Let’s talk projects, collaborations, or anything design!

Connect with me,

Let’s talk projects, collaborations, or anything design!

Copyright 2026 by Eva Ahmetaj

Copyright 2026 by Eva Ahmetaj

Copyright 2026 by Eva Ahmetaj